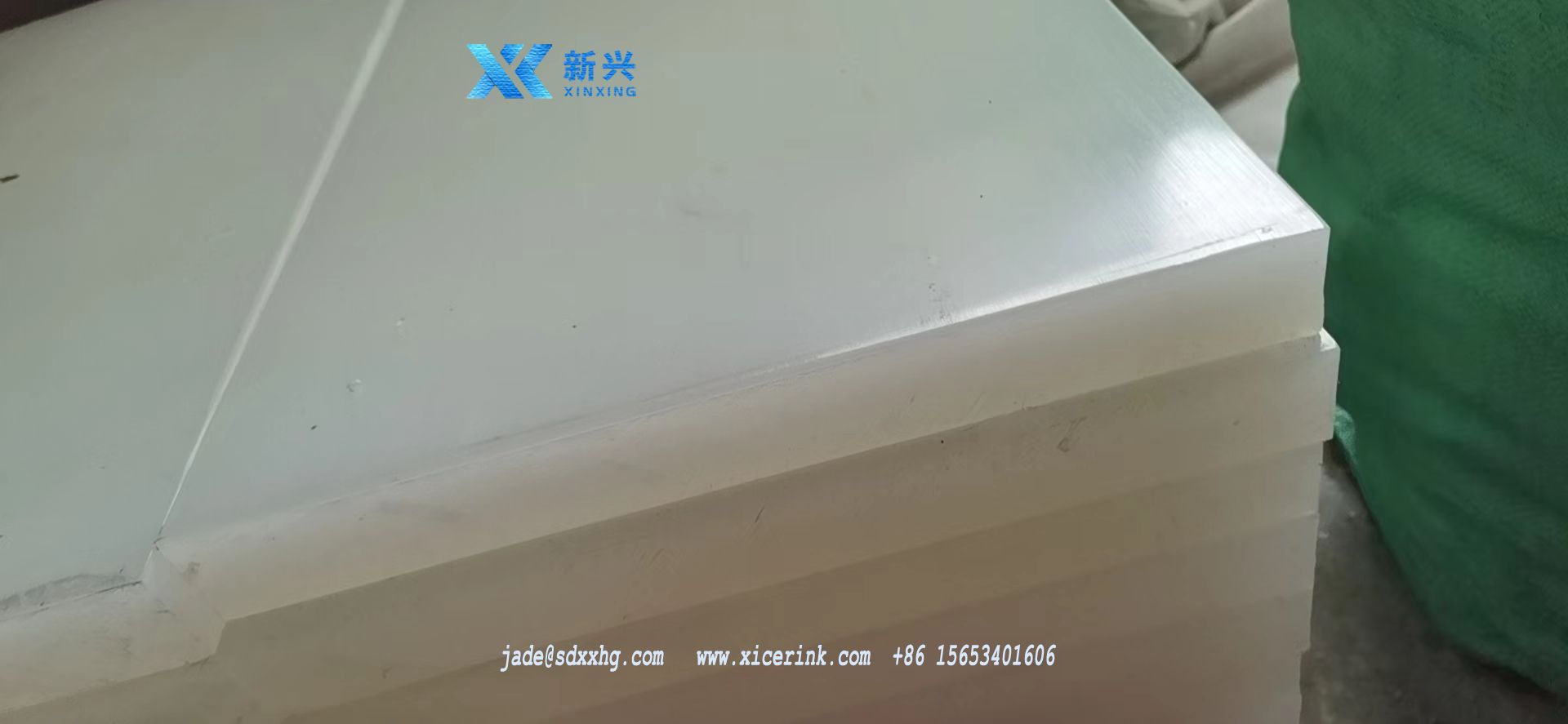

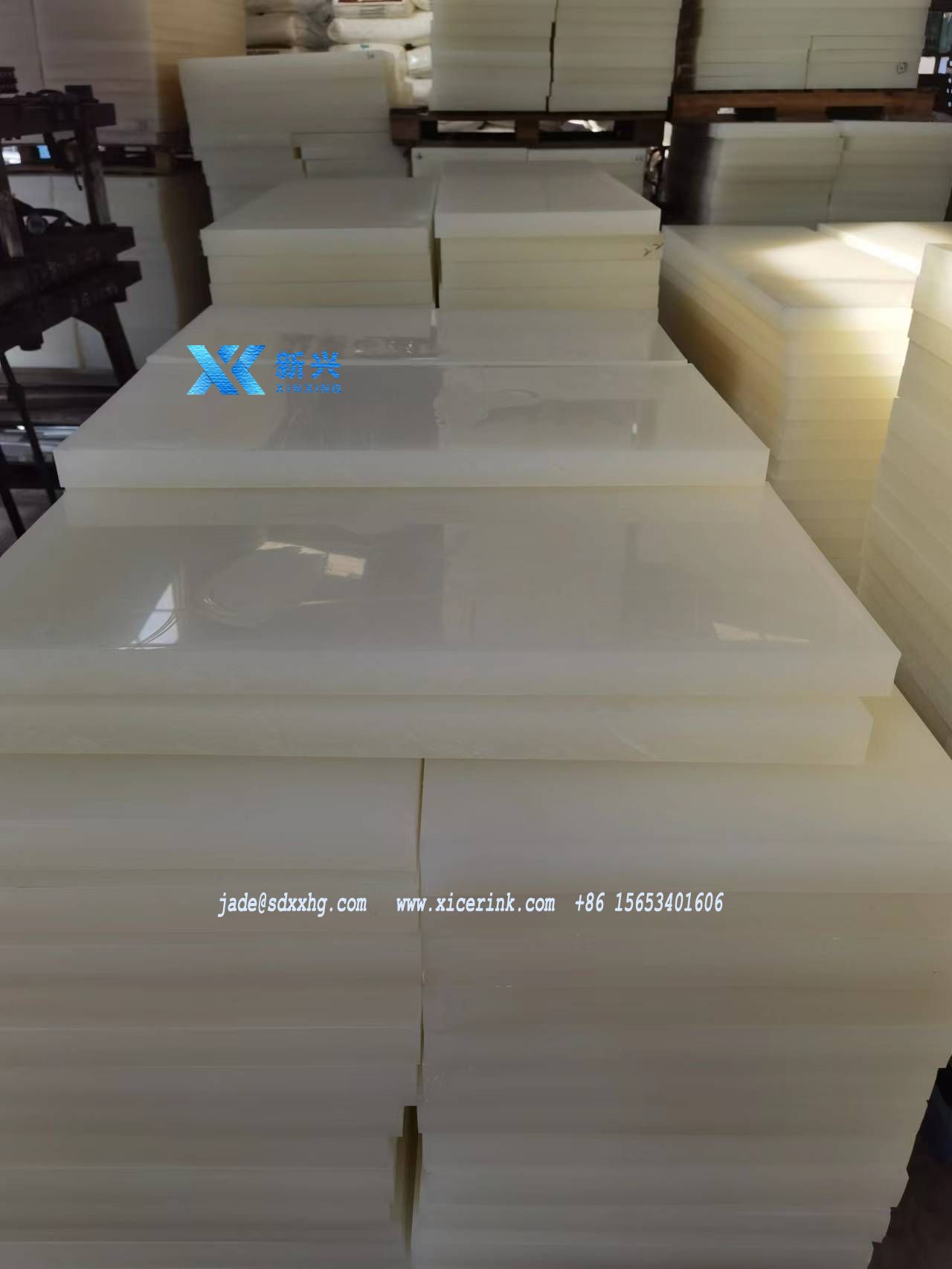

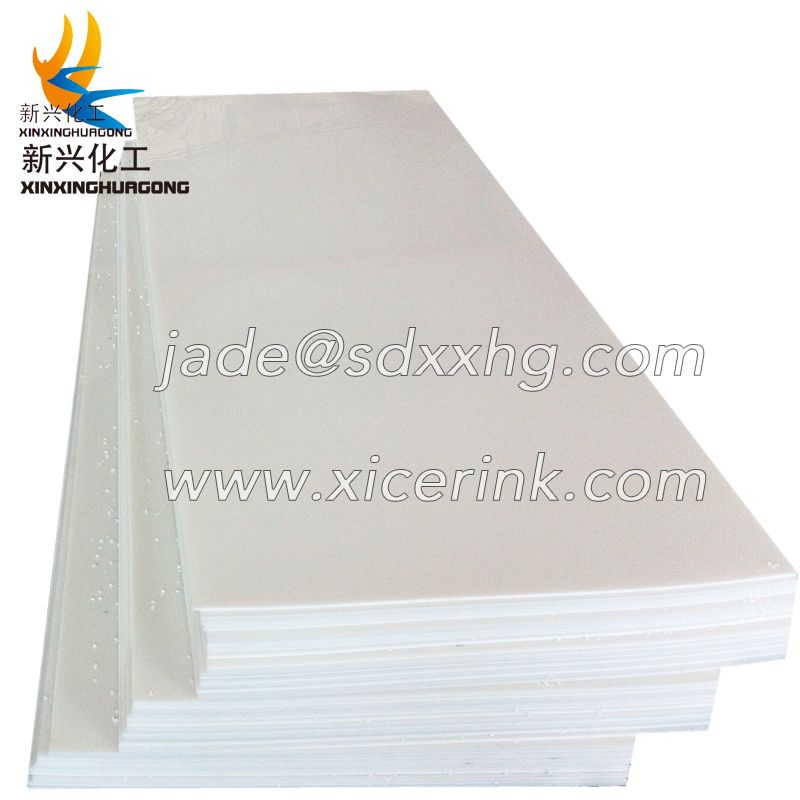

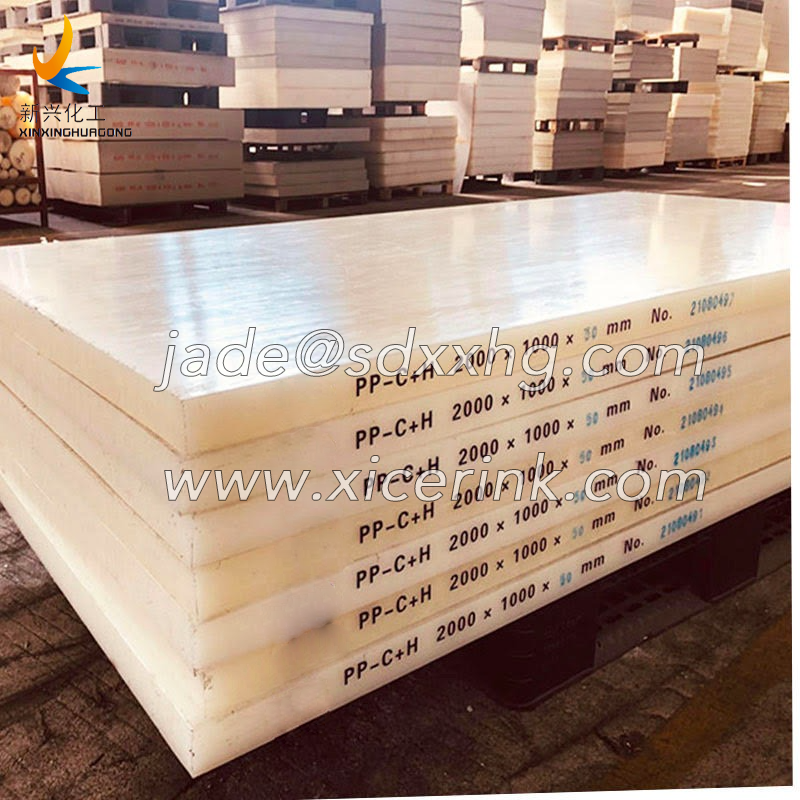

pp sheet pp plate pp board polyprolene

Polypropelene Standard Size Sheets, rods, welding rods, cut-to-size blocks

Polypropylene is an economical material that offers a combination of outstanding physical, chemical, mechanical, thermal and electrical properties not found in any other thermoplastic. Compared to low or high density polyethylene, it has a lower impact strength, but superior working temperature and tensile strength.

Product Overview

Xinxing Plastics is a leading plastic production factory ; PP can provider of welding services for customers throughout world market. We maintain extensive inventories of engineering, high-performance, and commodity plastics—including polypropylene—in a variety of forms and sizes to suit different plastic needs, including:

Sheets

Rods

Tubes

Angle Welding Rod

And various flame-retardant polypropylene material

Available Sizes

1000x2000mm; 1220x2440mm ; 1500x3000mm ; etc

Thickness : from 1mm to 200mm

Polypropylene (PP) is available in two basic types: homopolymer (PPH) or copolymer (PPC). Although similar in many respects, each type exhibits distinct differences in both appearance and performance.

At XINXING, we offer PPH suitable for use in a wide range of industrial applications, such as:

Automotive parts

Electrical components

Tanks

Fume Hoods

Scrubbers

Artificial straightening bracket

CHARACTERISTICS OF POLYPROPYLENE

Polypropylene is characterized by the following key attributes:

Resistance to chemicals. As polypropylene does not readily react with diluted bases and acids, it is suitable for use in the manufacture of containers for cleaning agents, medical products, and other chemically sensitive materials.

Elasticity and durability. The material’s elasticity and plasticity allow it to withstand pressure and stress without breaking.

Resistance to fatigue. Even after being subjected to bending, flexing, and torsion, parts made out of polypropylene retain their shape.

Insulation. PP’s high electrical resistance makes it suitable for use in electronic devices.

Transmissivity. The material is available in transparent and opaque variations, allowing it to accommodate a broader range of light transfer and aesthetic needs.

These qualities, along with a few others, are what make polypropylene suitable for a wide range of industrial and consumer applications, such as the manufacture of point-of-purchase (POP) displays, battery covers, chemical tanks, and complex pump components. Another advantageous properties of PP is its production versatility. The material can easily be machined and fabricated through several different fabrication techniques.

BENEFITS OF PPH

In addition to exhibiting the above characteristics, polypropylene homopolymer also brings its own unique set of qualities to the table. For example, compared to polypropylene copolymer, it demonstrates:

Higher strength-to-weight ratio

Better durability

Greater material stiffness

PPH is suitable for applications that require good resistance to impact, corrosion and chemicals, good weldability and processability, and/or food-safe standard compliance.

PPH FROM XINXING PLASTICS

At XINXING factory Industrial Plastics, we distribute polypropylene homopolymer sourced from industry-leading manufacturers.

For additional information about PPH or our other material offerings, contact us today. If you’re interested in partnering with us for your plastic fabrication or machining needs, fill out and submit the form below.

Typical Properties of Polypropylene PP Natural

| DETAIL | |||

|---|---|---|---|

| Description | Value | ||

| Material Type | Semi-Crystalline Thermoplastic | ||

| Chemical Name | PP Polypropylene | ||

| Additives | Unfilled | ||

| Color | Natural | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 0.95 |

| ASTM D792 | lb/in³ | 0.034 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | <.01 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 4800 |

| Tensile Modulus | ASTM D638 | psi | 195000 |

| Tensile Elongation at Break | ASTM D638 | % | 400 |

| Flexural Strength | ASTM D790 | psi | 7000 |

| Flexural Modulus | ASTM D790 | psi | 180000 |

| Compressive Strength | ASTM D695 | psi | 7000 |

| Hardness | ASTM D785 | NA | Shore D78 |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 1.2 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./°F | 6.2 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 52 |

| ASTM D648 | °F at 264 psi | 125 | |

| Melting Point Temp | ASTM D3418 | °C | 164 |

| ASTM D3418 | °F | 327 | |

| Max Continuous Operating Temp | °C | 82 | |

| °F | 180 | ||

| Minimum Operating Temp | °C | -10 | |

| °F | 14 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 0.76 |

| ASTM C117 | x 10^4 cal/cm-sec-°C | 2.6 | |

| Flammability Rating | UL94 | NA | HB |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Strength | ASTM D149 | V/mil | 500 |

| Dielectric Constant at 1 MHz | ASTM D150 | NA | 2.25 |

| Dissipation Factor at 1 MHz | ASTM D150 | NA | 0.0005 |

| Surface Resistivity | ASTM D257 | ohm/square | 10^12 |

| COMPLIANCE | |||

| Description | Value | ||

| FDA | Yes | ||

| USDA | Yes | ||

| NSF | No | ||

| 3-A Dairy | Yes | ||

| Canadian Food Inspection Agency | No | ||

| USP Class VI | No | ||

| OTHER | |||

| Description | Value | ||

| UV Resistant | No | ||

| Relative Cost | $ | ||

| Machinability | 1 | ||

Key Properties

Easily Fabricated

Excellent Dielectric Properties

High Compressive Strength

High Tensile Strength

Impact Resistant

Lightweight

Low Moisture Absorption

Non-Staining

Non-Toxic

Resists Most Alkalis and Acids

Resists Stress Cracking

Retains Stiffness and Flex

Limitations

Lower Impact Strength Than HDPE

Poor Resistance to Aromatic, Aliphatic and Chlorinated Solvents.

Applications

Chemical Resistant Tanks & Linings

Clean Room Walls, Floors & Ceilings

Die Cutting Pads

Filter Press Plates

Laboratory Consoles, Sinks & Ducts

Lavatory Partitions

Plating Barrels & Tanks

Prosthetic Devices

Pump Components & Housings

Railroad Crossing Components

Custom Tanks

Plastic Plating Tanks

Pickling Tanks

Galvanizing Tanks

Marine Tanks

RV Tanks

Custom Hydroponics

Polypropylene Plastic Containers

Plastic Mobile Tanks

Fire Truck Water Tanks

Restroom Trailers

Hydroponics

Xinxing is the largest Group manufacturer of engineering plastics in China. Xinxing's main products include UHMWPE & HDPE sheets, double colour HDPE sheets and parts, as well as custom machined plastic parts such as, UHMWPE Synthesis of ice, PE hockey shooting board, plastic ice rink barrier, ICE RINK system, ICE HOKCEY RINK SYSTEM, FLOORBALL RINK, SOCCER REBOUNDER etc. Email: jade@sdxxhg.com

Product Name: pp sheet pp plate pp board polyprolene